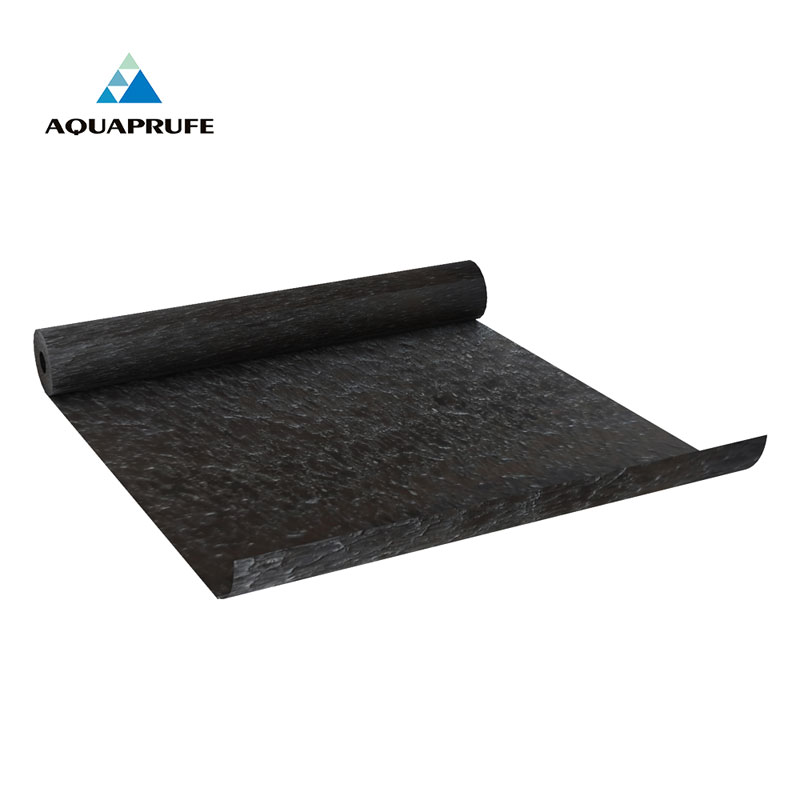

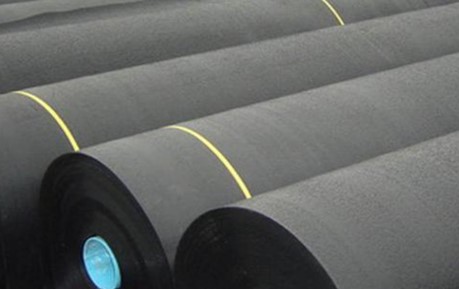

Double-Textured HDPE Geomembrane

- Aquaprufe

AG-TGⅡ Double-Textured HDPE Geomembrane is made with virgin PE resins, together with carbon black and other additives. The product meets GRI-GM13 Standard.

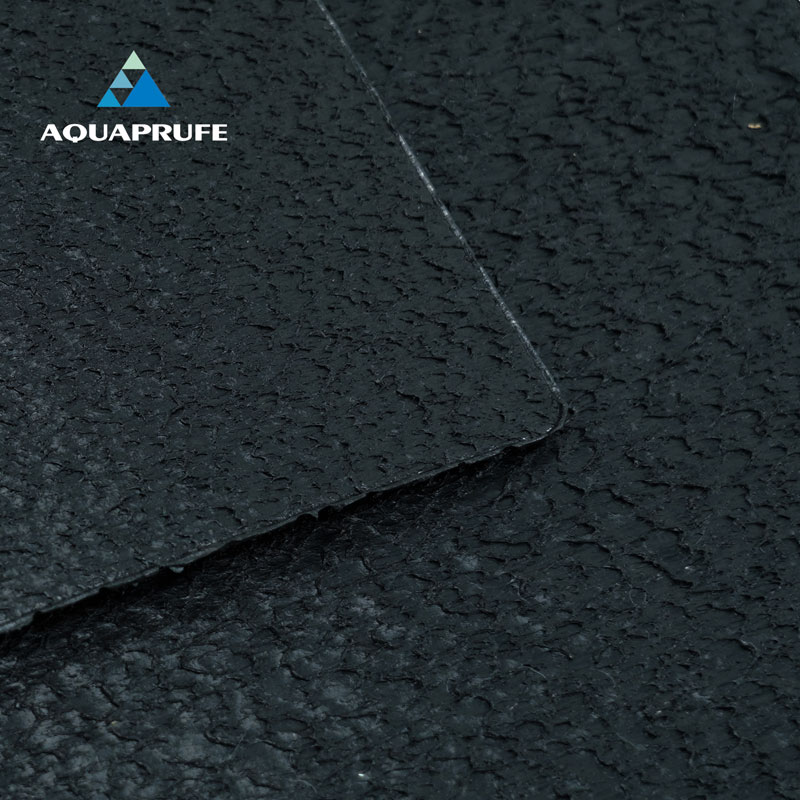

Both sides of AG-TGⅡ are textured. It is produced by the advanced technique of 4-layer extrusion and film blowing, which ensures even thickness. And the asperity is flocculent PE sprayed by nitrogen, enabling it to maintain a better tear resistance performance. The texture provides great friction force to prevent sliding. The 10cm seam part is made smooth to facilitate welding.

Uses

AG-TGII is suitable for anti-seepage projects with high anti-sliding requirements, especially those in steep, slope areas and those with soil coverage after implementation.

Typical applications would be municipal environmental protection, water conservancy, seepage proofing works of projects including aquaculture, waste disposal, dam, metallurgy, petrochemical, mining, transport, landscaping, etc.

Advantages

Anti-aging & anti-UV

Resistant to oxidation, chemicals and bio-enzyme degradation

High tensile strength & extensibility

High friction force & anti-sliding on the textured side

Great Low-temperature flexibility, no brittle failure even under -70°C

Great impermeability, with permeability coefficient of <10-13g·cm/ (cm2·s·Pa)

Smooth seam to ensure tight welding

Customized color available for each layer

Properties

PROPERTY | TEST METHOD | TEST VALUE | |||

1.00 mm | 1.50 mm | 2.00 mm | 2.50 mm | ||

Thickness (min. avg.) - mm | D5994 | nom. -5% | nom. -5% | nom. -5% | nom. -5% |

| -15 | -15 | -15 | -15 | |

Asperity Height mils (min. avg.) - mm | D7466 | 0.40 | 0.40 | 0.40 | 0.40 |

Formulated Density (min. avg.)- g/cm3 | D1505/D792 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties (min. avg.) | D6693 Type Ⅳ | ||||

| 15 | 22 | 29 | 37 | |

| 10 | 16 | 21 | 26 | |

| 12 | 12 | 12 | 12 | |

| 100 | 100 | 100 | 100 | |

Tear Resistance (min. avg.) - N | D1004 | 125 | 187 | 249 | 311 |

Puncture Resistance (min. avg.) - N | D4833 | 267 | 400 | 534 | 667 |

Stress Crack Resistance – hr. | D5397 | 500 | 500 | 500 | 500 |

Carbon Black Content (range) - % | D4218 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

Oxidative Induction Time (OIT) (min. avg.) | |||||

(a) Standard OIT – min. | D8117 | 100 | 100 | 100 | 100 |

(b) High Pressure OIT – min. | D5885 | 400 | 400 | 400 | 400 |

Oven Aging at 85°C | D5721 | ||||

(a) Standard OIT ( min. avg.) - % retained after 90 days | D8117 | 55 | 55 | 55 | 55 |

(b) High Pressure OIT ( min. avg.) - % retained after 90 days | D5885 | 80 | 80 | 80 | 80 |

UV Resistance | D7238 | ||||

| D5885 | 50 | 50 | 50 | 50 |

Application Procedures

Substrate cleaning - Geomembrane positioning - Welding - Engineering inspection

Packaging

Available from 1.00mm to 3.00mm in thickness, and up to 8m in width for each roll.

Storage

AG-TGII is designed to last 70 years under natural conditions and the service life remains the same if it is not stored or used in harsh environments. The optimal storage environment would be shady, dry and at room temperature.