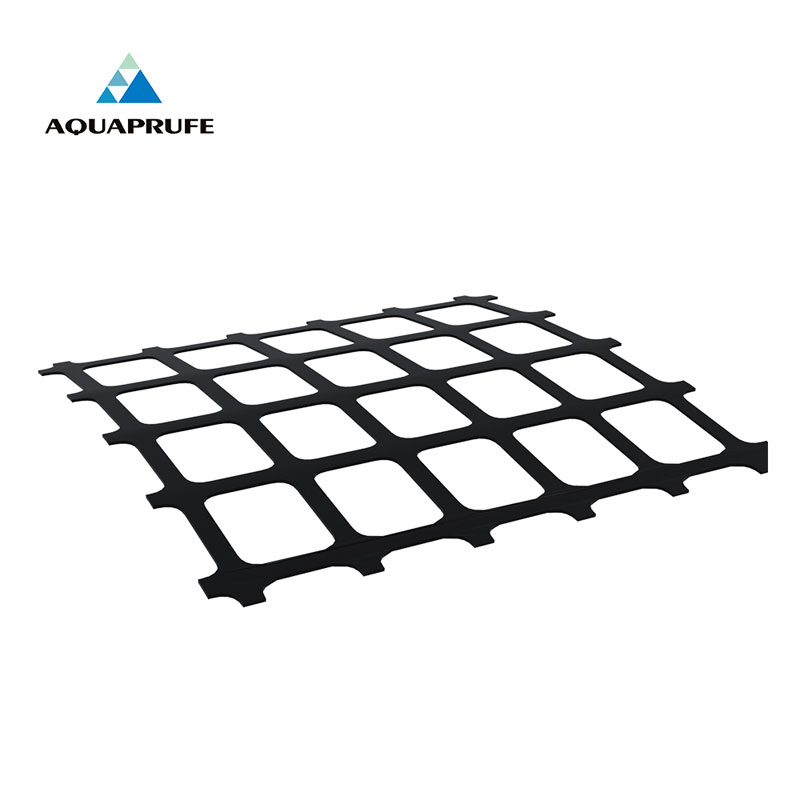

Biaxial Geogrid

- Aquaprufe

AG-BG Biaxial Geogrid is made with polypropylene (PP) or polyethylene (PE), together with carbon black and other additives. It has latticed ribs and square meshes.

It is made of polymer thin sheets punched with regular hole meshes and then stretched both longitudinally and laterally. The structure provides high tensile strength in both directions, which creates a great chain system for force bearing and diffusion. The product is especially suitable for reinforcement of large permanent load-bearing foundations. AU-UG comes in multiple types with different tensile strengths.

Uses

AG-BG Biaxial Geogrid is suitable for reinforcement of large permanent load-bearing foundations.

Typical applications would be subgrades and surfaces of roads, railways and airports; foundations of large parking lots and dockyards; slopes, pits and mining sites; secondary reinforcement upon a layer of uniaxial geogrid.

Advantages

Effective transmission of force & great solidity to prevent soil deformation

Even load transfer to stabilize subgrades

Anti-aging & anti-UV

Resistant to oxidation, chemicals & bio-enzyme degradation

Excellent low-temperature stability, all indicators remain qualified after 200 times of repeated hot and cold cycles down to -50 °C

Easy to apply

Properties

PROPERTY | TEST METHOD | TEST VALUE | ||||

10-10PP | 20-20PP | 30-30PP | 40-40PP | 50-50PP | ||

Ultimate Tensile Strength – kN/m | D6637 | 10 | 20 | 30 | 40 | 50 |

Tensile Strength at 2% Strain - kN/m | D6637 | 3 | 7 | 11 | 14 | 18 |

Tensile Strength at 5% Strain - kN/m | D6637 | 5 | 14 | 21 | 28 | 35 |

Resistance to Installation Damage -% | D5818 | 95 | 95 | 95 | 95 | 95 |

Resistance to Long-Term Degradation - % | EPA9090 | 100 | 100 | 100 | 100 | 100 |

Resistance to UV Degradation -% | D4355 | 100 | 100 | 100 | 100 | 100 |

Carbon Black Content - % | D4218 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

Application Procedures

Substrate preparation - Geogrid positioning - Fixation - Engineering inspection - Protection

Packaging

Available from 10-10kN/m to 50-50kN/m in tensile strength. 2-6m in width, and 50m in length for each roll.

Storage

AG-BG is designed to last no less than 70 years under natural conditions and the service life remains the same if it is not stored or used in harsh environments. The optimal storage environment would be shady, dry and at room temperature.