What is Waterproof Material?

Waterproof material refers to materials that can prevent water or other liquids from penetrating. They are widely used in many fields such as construction, transportation, clothing, and electronic products, and are indispensable and important materials in modern industry and daily life.

This article will systematically explain the concept, types, performance, and role of waterproof materials in various applications to help readers fully understand the importance of waterproof materials.

What is waterproof material?

Definition and basic principles of waterproof materials:

Waterproof materials, as the name suggests, refer to a class of materials that can prevent water from penetrating. The basic function of these materials is to form a barrier to prevent water or other liquids from entering a specific space, thereby protecting the objects or environment in the space from the influence of water. The waterproofness of waterproof materials is usually achieved through their own structure, chemical properties, or surface treatment.

The mechanism of action of waterproof materials can be divided into two categories: barrier type and absorption type. Barrier waterproof materials prevent water penetration by forming a dense, non-porous surface, such as plastic film and rubber. Absorption waterproof materials achieve waterproof purposes by absorbing and locking water, such as certain absorbent polymers.

What are the types of waterproof materials?

According to the composition, structure and application scenarios of the materials, waterproof materials can be divided into:

1. Organic waterproof materials

2. Inorganic waterproof materials

3. Composite waterproof materials

4. Nano waterproof materials

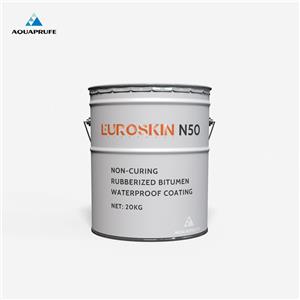

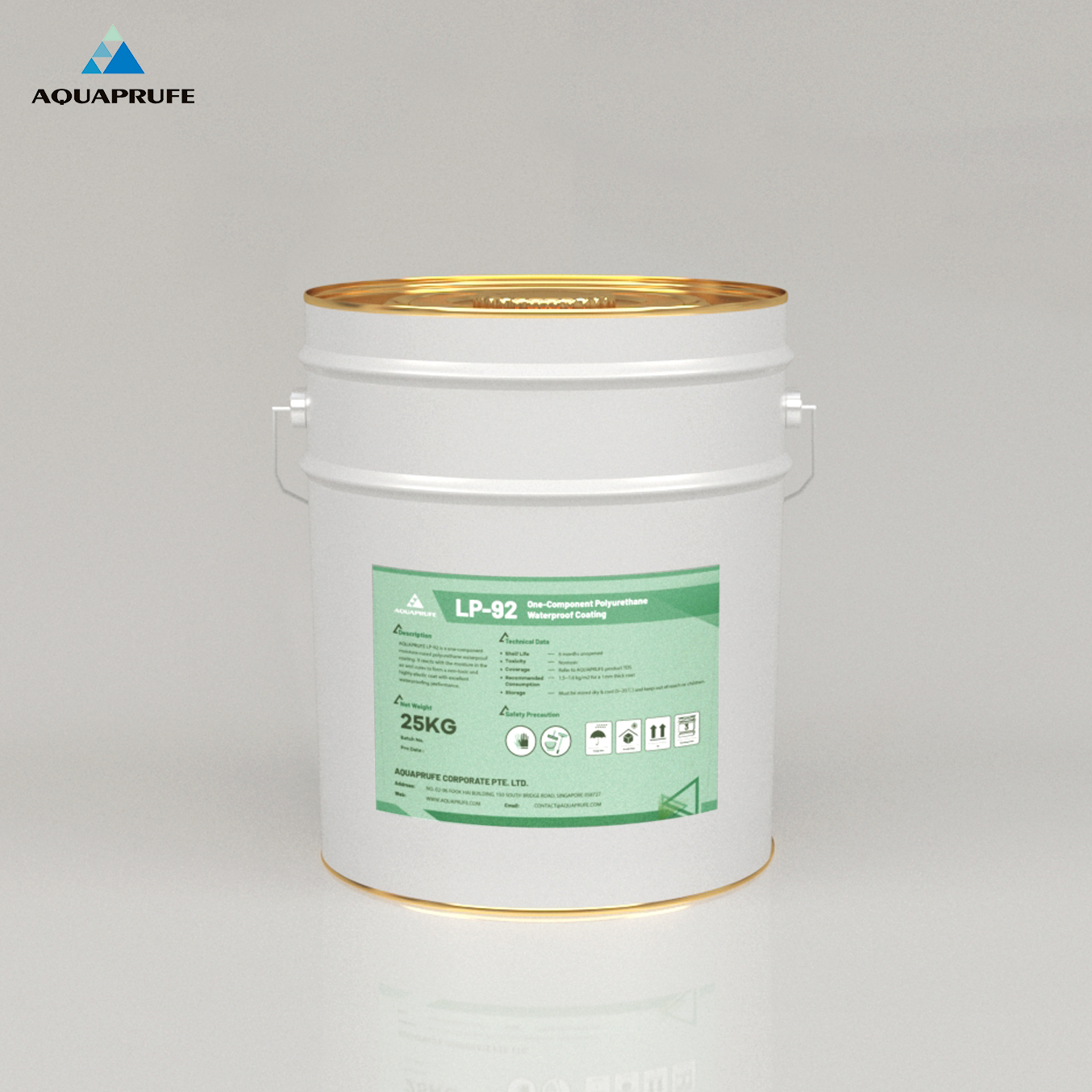

● Organic waterproof materials mainly include asphalt and synthetic polymer materials (such as polyurethane, polyvinyl chloride, polyethylene, etc.). These materials have good flexibility and durability through chemical treatment. Asphalt waterproof materials are widely used in building roofs and underground waterproof projects, and are favored for their excellent weather resistance and low cost.

● Inorganic waterproof materials mainly include cement-based waterproof materials and silicate materials. Cement-based materials are often used for waterproofing of underground projects and concrete structures because of their good bonding with the building body. Silicate materials have good high temperature resistance and corrosion resistance, and are suitable for waterproofing projects in special environments.

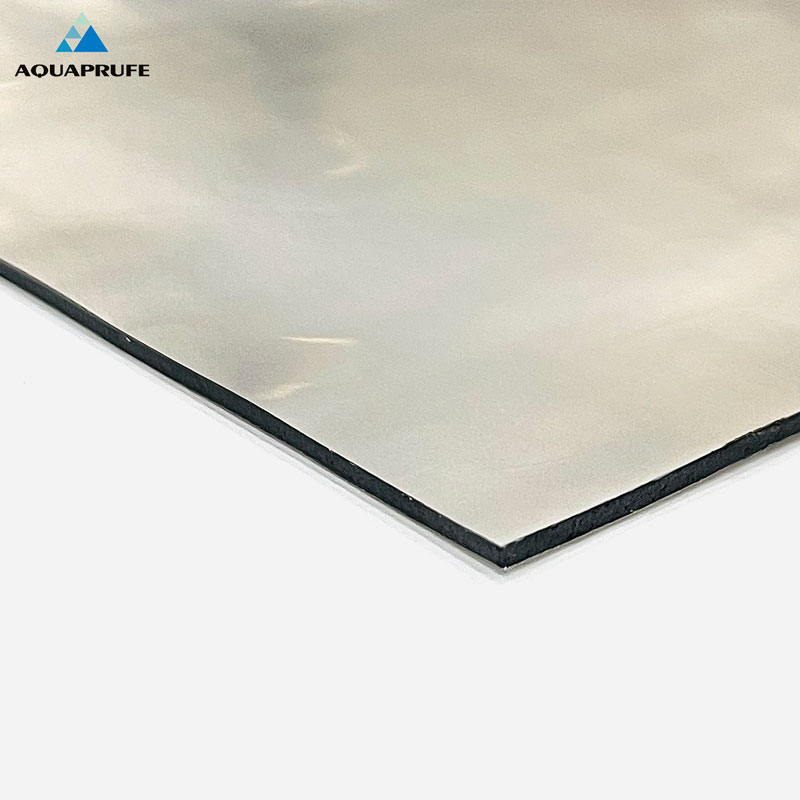

● Composite waterproof materials are composed of organic and inorganic materials, and have the advantages of both. Typical composite materials include modified asphalt rolls, composite membranes, etc. This type of material is usually used in high-demand waterproof projects to provide more reliable protection.

● With the development of nanotechnology, nano waterproof materials have gradually become the new favorite in the field of waterproof materials. Nano waterproof materials are modified by the surface of nanoparticles to form a super-hydrophobic surface, which can effectively prevent water penetration while maintaining good air permeability. This type of material is mostly used for waterproof protection of high-end electronic products and the manufacture of special textiles.

What are the key performance indicators of waterproof materials?

Waterproofness is the primary indicator for measuring waterproof materials, which is mainly evaluated by testing the permeability of materials under water pressure. Materials with excellent waterproof performance should be able to remain impermeable under long-term high water pressure conditions.

Secondly, the durability of waterproof materials includes their stability under various environmental conditions, such as high temperature, low temperature, ultraviolet rays, chemical erosion, etc. The durability of the material is directly related to the service life of the waterproof layer, especially in the fields of construction and transportation.

For waterproof materials used in construction, adhesion is another important indicator. The material should be able to firmly bond with the base material (such as concrete, metal, etc.) to prevent leakage caused by poor bonding. In addition, the flexibility of the waterproof material determines whether it can maintain the waterproof effect when the base material is deformed, especially in earthquake-resistant buildings, bridges and other structures that need to withstand deformation, flexibility is particularly critical.

With the increase of environmental awareness, the environmental protection of waterproof materials has also become a focus of attention. Non-toxic, harmless and recyclable waterproof materials are increasingly favored by the market.

What are the application areas of waterproof materials?

In construction projects, the application of waterproof materials is crucial. Whether it is a roof, basement, exterior wall or bathroom, the quality of waterproof materials directly affects the service life and living comfort of the building. Commonly used building waterproof materials include waterproof membranes, waterproof coatings, cement-based waterproof materials, etc.

In the field of transportation, waterproof materials are widely used in facilities such as roads, bridges, tunnels and airport runways. Waterproof materials not only protect these infrastructures from water erosion, but also improve their safety and durability. For example, waterproof materials in highway tunnels need to withstand long-term high humidity environments and cannot affect the stability of the structure.

The waterproofness of electronic products is one of the important indicators to measure their quality. With the increasing demand for the diversified use environment of electronic products, the waterproof design of mobile phones, smart watches and other devices has become increasingly important. Nano waterproof materials are widely used in the waterproof protection of such products because of their good air permeability and no effect on the heat dissipation of electronic components.

Waterproof fabrics are widely used in outdoor sportswear, raincoats, tents and other products. By adding waterproof coating or composite waterproof membrane to the surface of fabric, waterproof clothing can effectively prevent water penetration while maintaining good breathability and comfort.

In the agricultural field, waterproof materials are often used for anti-seepage treatment of reservoirs and irrigation canals. In the industrial field, waterproof materials are used for anti-corrosion and waterproof protection of various equipment and pipelines, such as oil pipelines and chemical storage tanks.

Development history of waterproof materials

The development of waterproof materials has evolved with the progress of human civilization. Early humans mainly relied on natural materials such as soil and resin for simple waterproofing. With the development of technology, artificial synthetic materials have gradually become the mainstream, especially since the 20th century, the rapid development of the chemical industry has greatly promoted the diversification and performance improvement of waterproof materials. At present, with the continuous advancement of materials science, waterproof materials are developing in a more efficient, environmentally friendly and intelligent direction.

Conclusion

As an indispensable part of modern industry and daily life, waterproof materials are playing an increasingly important role. Whether in construction, transportation, electronic products or clothing, waterproof materials play a key role.

In the future, with the advancement of technology and changes in market demand, waterproof materials will continue to innovate and develop, bringing more exciting applications and possibilities.