How Do We Achieve the High Quality of Geomembranes?

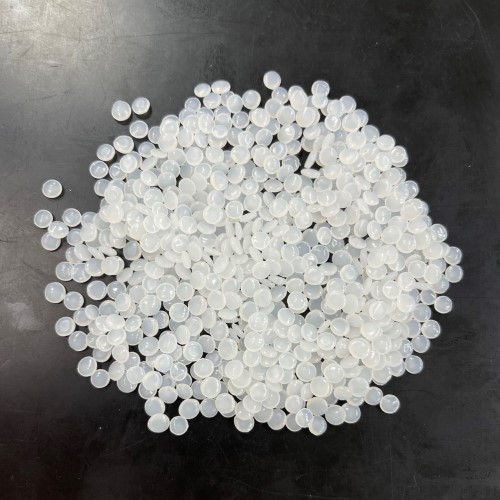

1. Excellent raw materials

Aquaprufe uses raw materials supplied by chemical giants, such as Chevron Philips, Borealis, and Cabot. We use 100% virgin PE resins to produce high-quality geomembranes.

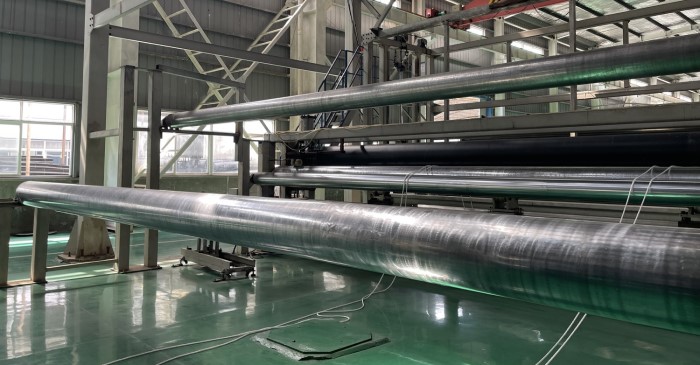

2. Advanced production techniques

Aquaprufe’s geomembrane production line is fully automated. We adopt the advanced four-layer co-extrusion and nitrogen-roughening and blown-film techniques using PLAMEX equipment. The thickness of the geomembrane and the asperity height of the textured geomembrane can be adjusted by computer. The intactness of geomembrane and uniformity of thickness is automatically detected on-line along with the production process.

Our advanced production and monitoring techniques ensure the flawlessness of products and effectively lower the margin of thickness error to ±4%, which is much less than that of the GRI GM-13 standard.

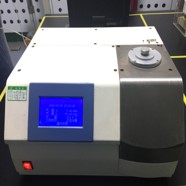

3. A rigorous quality testing system

Every roll of geomembrane can be tracked in our production and control system. We conduct one lab test for every 10,000 m2 produced and the corresponding samples will be kept for 5 years in case of any after-sale problem.

We run a professional testing lab for rigorous quality control. The lab is fully equipped with testing instruments, able to conduct a complete set of tests including environmental stress cracking tests, oven aging tests, UV aging tests, carbon black content tests, oxidation induction time tests, right angle tear tests, puncture resistance tests, tensile performance tests, etc.

Aquaprufe pursues the highest quality at every stage of production and delivery. Please feel free to contact us for any inquiries about our products.